2022-11-14 14:25:52

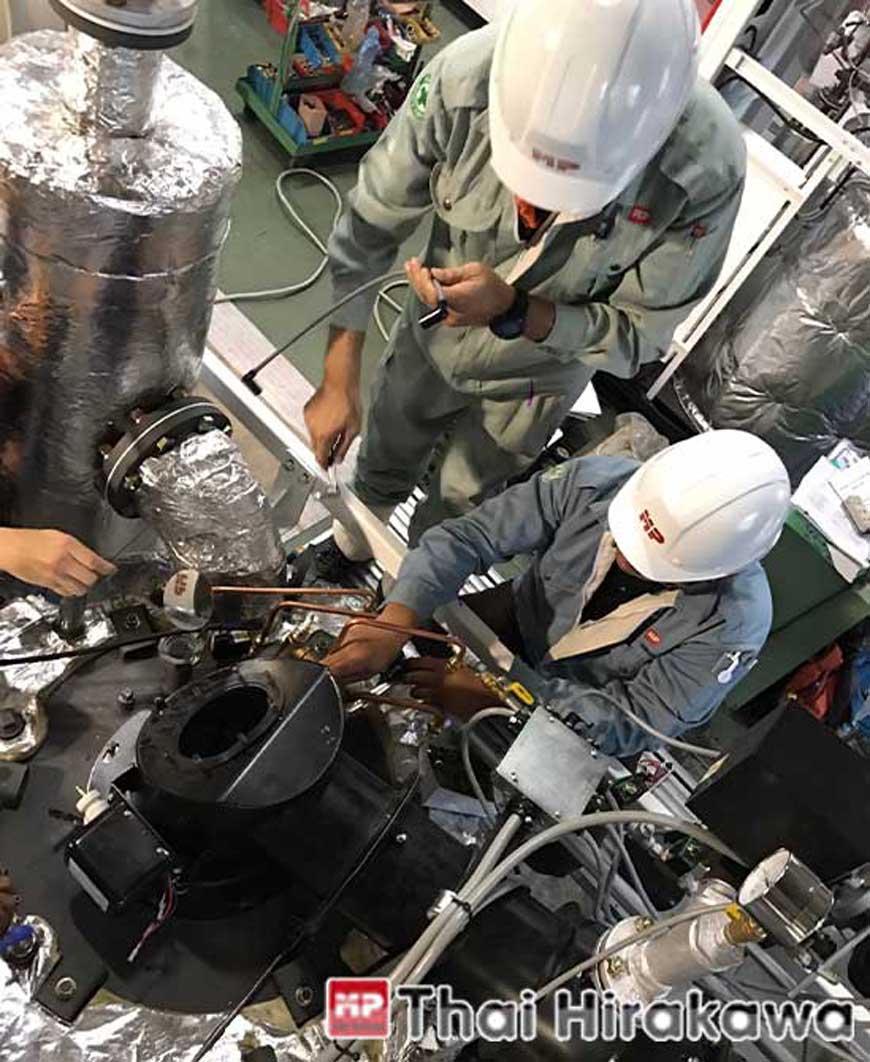

Boiler or Steam Generator is one of the most popular industrial machines widely used in factories. Due to its various benefits, such as increasing production capacity and reducing operational costs, many business owners consider using boilers a worthwhile investment. Naturally, like all machinery, boilers are subject to wear and tear from regular use. Therefore, regular inspection and maintenance are crucial. It is essential to hire qualified engineers with expertise in boiler systems to carry out inspections and maintenance. Boilers operate under high heat and pressure, and if improper tools or non-standard methods are used, they can potentially explode.

Steps for Boiler Inspection and Maintenance include:

• Regularly inspect the boiler exhaust pipe. If leaks are found, fix them immediately to prevent emissions.

• Check the burner flame. If the flame is unstable or unusual, it should be fixed. A properly functioning boiler will have a steady flame.

• Randomly analyze exhaust gases to assess combustion quality and compare monthly for abnormal changes.

• Check the boiler body for abnormal heat. High external temperatures may indicate excessive internal pressure or temperature, risking explosion.

• Inspect the water tank to ensure it has been treated and monitor water quality.

• Ensure the boiler is installed in a well-ventilated and open area for proper air combustion.

• Check all auxiliary equipment and replace any damaged parts immediately.

• Clean the filters and check whether they can still function properly.

• Inspect lubrication in all parts. Apply grease as needed and avoid abnormal sounds or dryness.

• Inspect and tighten drive belts. Adjust tension if they are too loose.

• Check the fuel distribution system and all related components.

• Clean the exhaust duct to remove soot buildup, which reduces efficiency.

• Check pipes, valves, and connections for any leaks of liquids or gases.

• Check lubricants in all areas. Dry parts reduce efficiency—apply grease as needed.

• Inspect the boiler tank for cracks or leaks. Old tanks should be replaced immediately to prevent rupture.

• Keep the oil tank filled to prevent condensation.

• Check the sight glass for cracks or leaks and replace if damaged.

• Ensure all safety systems and emergency alarms are functioning. Replace if in doubt.

• Clean all boiler-related equipment regularly to prevent clogging and ensure smooth operation.

• If using oil fuel, inspect and clean the oil pump head to prevent clogging.

• Check all electrical and electronic connections to prevent fire hazards that could cause explosions.

• If using gas fuel, clean the exhaust duct of soot to maintain full performance.

• Conduct general boiler inspections and clean the condensate receiver.

• Thoroughly inspect the feedwater pump. Replace if damaged.

• Clean the fire-facing walls using appropriate methods, dry, and coat with anti-corrosion spray.

Regular boiler inspection and maintenance is essential for all factories. A major inspection should be conducted at least once a year to prevent hazards to personnel and property. It also helps maximize machine performance.

If you’re looking for a supplier or company for boiler inspection and maintenance, Thai Hirakawa Co., Ltd. is a recognized expert in boilers with internationally accepted quality standards under the brand "MP Boiler". We provide complete services from manufacturing, sales, installation, and consultation to meet your budget and needs.

------------------------------------------------------------------------------------------

Related Articles

• Proper Boiler Installation According to Engineering Standards: Efficient and Cost-effective

• Did You Know? What Types of Fuel Can Be Used in Steam Generators?

• Thai Hirakawa – A Leading Boiler Industry Expert with Outstanding Services